What we do

Kaizen support

We support the sustainable development of companies through TPS Kaizen

- Companies aspiring to enhance productivity and quality.

- Companies striving to foster a Kaizen culture and fortify their business foundation.

- Companies in search of TPS Kaizen solutions customized for their operations.

Why us?

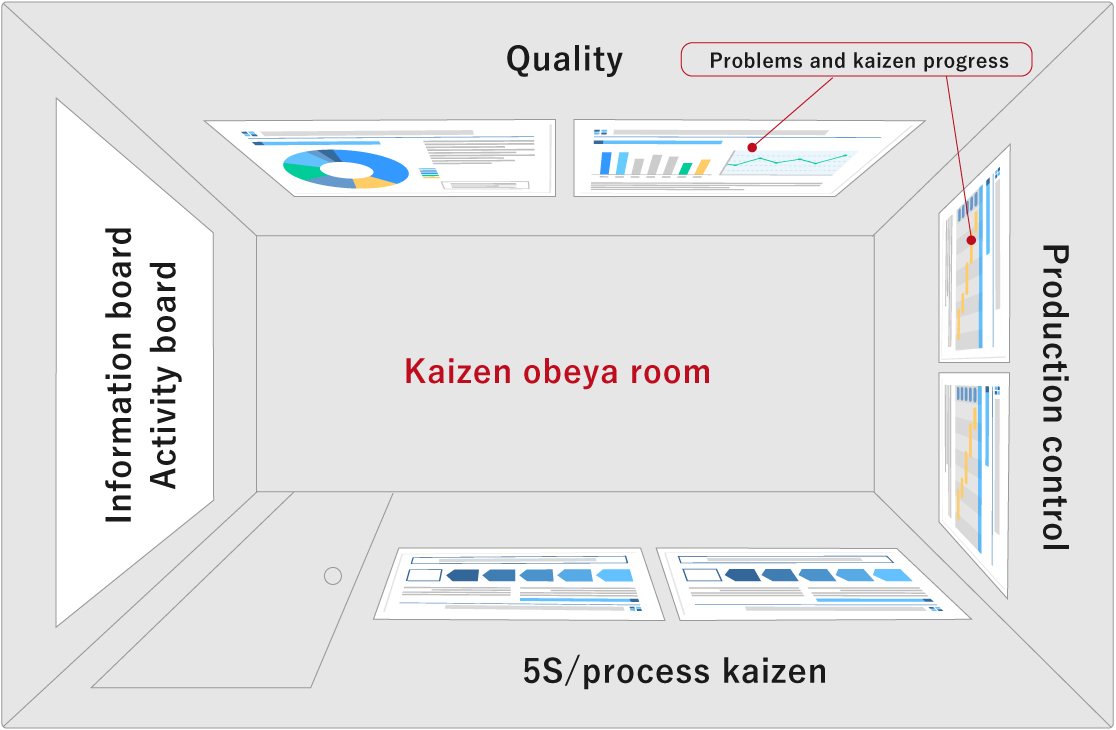

- With implementation of Obeya-system and Visual management, we promote effective Kaizen activities.

- We achieve sustainable Kaizen activities through our unique method that places employee satisfaction, empowerment and motivation at the core of our initiatives.

- Our tried-and-true methods and tools make TPS concepts work for any industry or task

“Obeya" refers to a large room, but in the context of Kaizen, it represents a mechanism where experts or relevant stakeholders gather across the organization (even if it's a virtual room, it can signify a cross-functional team) to visualize challenges hindering goal achievement, and efficiently implement Kaizen with the participation of relevant people, aiming to eliminate obstacles.

How we can help: The Range of Services and Methods/Tools

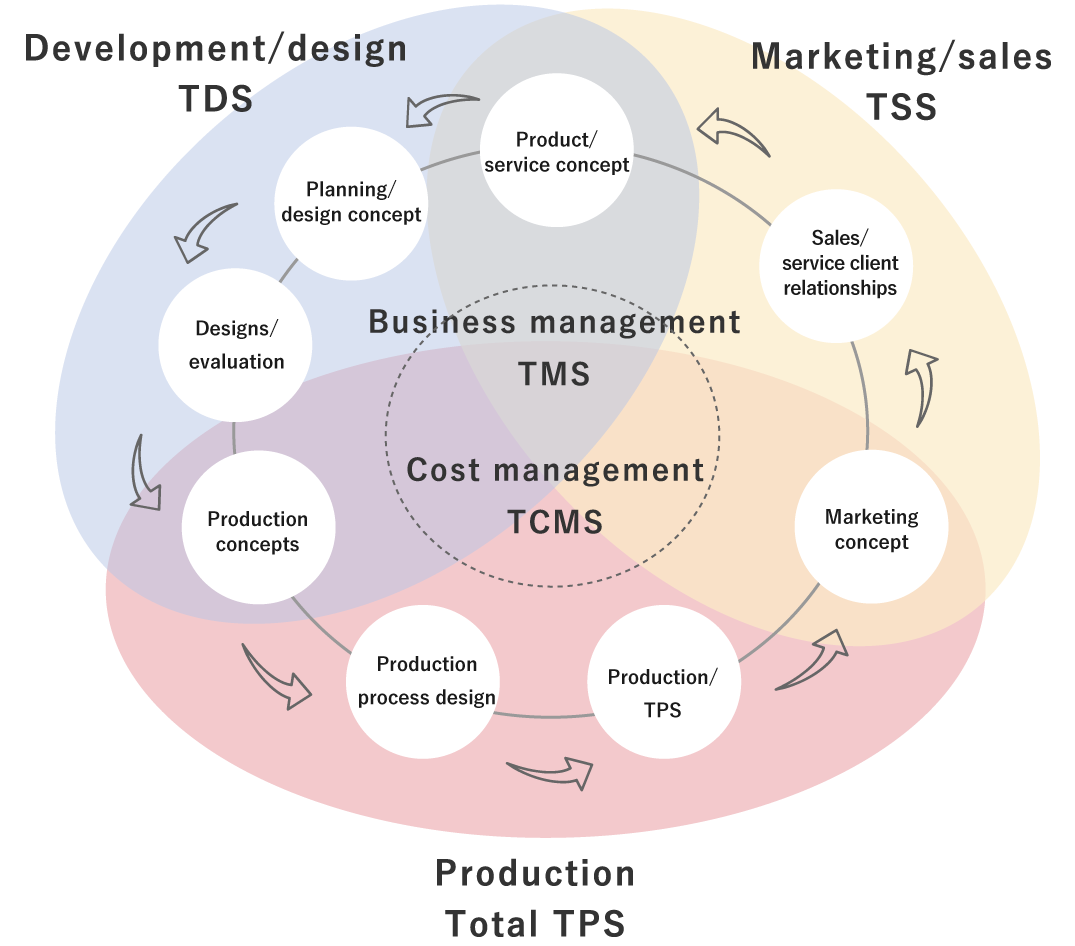

We have developed unique TPSmethods and tools that can be applied throughout the entire value chain of corporate activities, including development/design, production, business management, cost management, marketing, sales, and more.

Our seasoned consultants are available to assist you in enhancing the innovation and efficiency of your company.

Business management →Toyota Way Management System (TMS)

Cost management →Toyota Cost Management System (TCMS)

Development/design →Toyota Development System (TDS)

Production →Total Toyota Production System (Total TPS)

Marketing/sales →Toyota Sales System (TSS)

Rest assured, if your company was outside the automotive industry and not familiar with TPS concept.

We have introduced TPS Kaizen in the optimal form for clients in various industries and business sectors. We will customize Kaizen plan for your company.

Leveraging solid methods and extensive experience, we contribute to the sustainable development of corporate value, including productivity improvement and quality enhancement.

The process

step#1

Contact

Reach out to us online or by phone.

step#2

Meeting

We’ll schedule a meeting to better understand your challenges and concerns.

step#3

Factory diagnostics

Our consultant will visit your company's site and conduct a factory diagnosis.

step#4

Kaizen proposal

Our consultant will visit your company's site and conduct a factory diagnosis.

step#5

Contract

If you are satisfied with the proposal, we will proceed to the contract stage.

step#6

Kaizen support

We will implement Kaizen support based on the agreed-upon Kaizen plan.